|

|

Our company is focused on high quality products

that meet our customer’s needs at a great value.

Our company has a broad range of technological

knowledge and this is exhibited through our wide

selection of product offerings. Technological

advancement and quality has always been the

driving force behind our factory's development.

|

| |

|

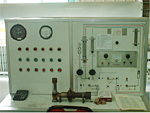

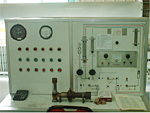

High-efficiency Filter Detector-Na Flame

Test Desk

|

The Na flame test desk was manufactured

based on the standard test method on the

performance of High- efficiency

Air Filter-Permeation rate & Resistance, with

the aerosol of the sodium chloride water

solution. It intrigues Na with H2 flame at a

high temperature to let it give off a

characteristic ray of about 589nm, and transfers

it to the current value by the optoelectronic

converter so as to get the initial efficiency of

each filter. Our factory uses the Na flame test

desk to detect each high-efficiency filter with

clapboard before ex-work. efficiency

Air Filter-Permeation rate & Resistance, with

the aerosol of the sodium chloride water

solution. It intrigues Na with H2 flame at a

high temperature to let it give off a

characteristic ray of about 589nm, and transfers

it to the current value by the optoelectronic

converter so as to get the initial efficiency of

each filter. Our factory uses the Na flame test

desk to detect each high-efficiency filter with

clapboard before ex-work. |

| |

| Filter Detector Used for Ventilation

|

| Common test desk for ventilation

is designed and manufactured according to Europe

standard EUROVENT4/9-93. In order to detect the

overall efficiency of the filter, it uses the

Laskin nozzle to produce test aerosol and takes

the test filter samples from the beginning to

the end status via laser particle counter. Our

factory uses the device for sample testing of

common filters used for ventilation in terms of

GB/T 2828-2003 Counting Sample Detection

Program. |

|

| |

| High-efficiency Filter Detector-MPPS

Test Desk |

The device was imported by the use of a

leading test method of high-efficiency filter

internationally-counting scan method. Testing

dust source is the scattering droplets produced

by Laskin nozzle. By using the laser

particle counter with large flux to scan and

test the whole wind-out surface, the counter

gives out the quantity and particle diameter of

each dust. laser

particle counter with large flux to scan and

test the whole wind-out surface, the counter

gives out the quantity and particle diameter of

each dust.

This method not only can be used to test the

average efficiency of the filter but also can compare the local

efficiency of every point. Our factory uses the device to detect all

specifications of high-efficiency filters without clapboard before

ex-work. |

| |

|

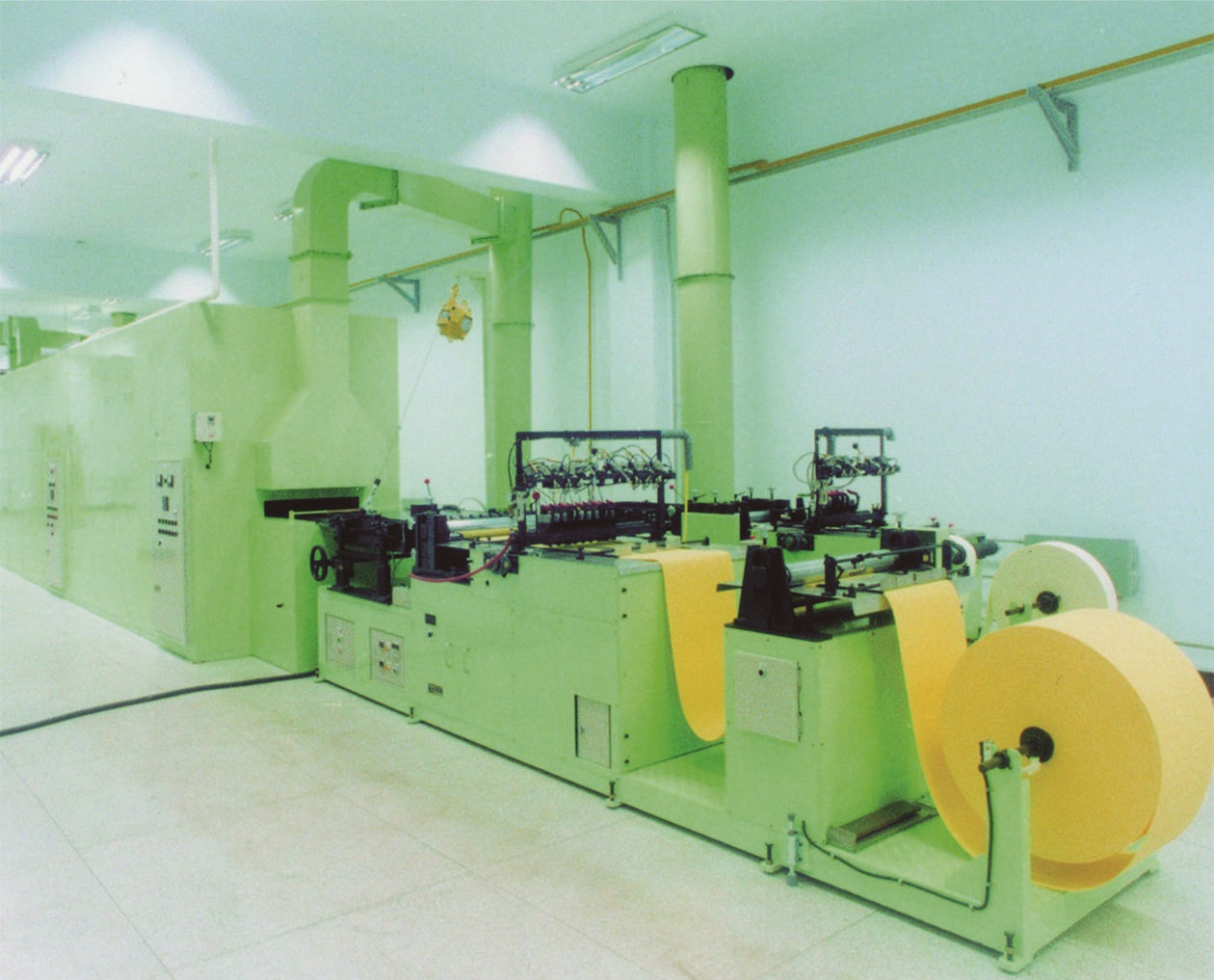

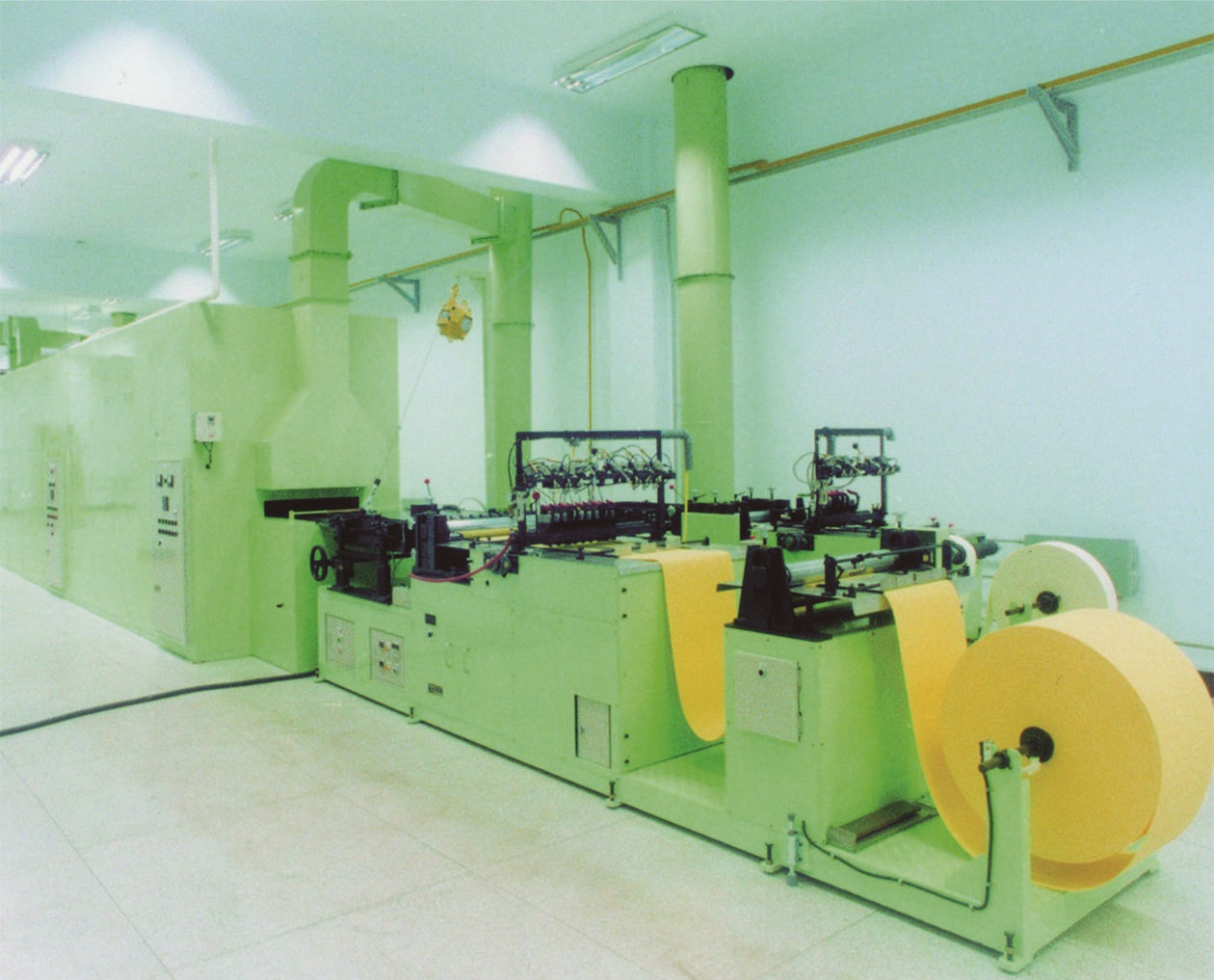

Foaming Device

|

| It consists of a

two-solution auto-mixing spitting device and

several digital control worktables and it is

used for integrative sealing equipment. |

|

| |

| Glue Filling Device |

| It consists of the two-solution auto-mixing spitting device, the digital control worktable and the ring roller, which is the sealing device for glue filling of the filters. |

|

| |

|

Chemical

Test Desk

|

The Chemical Test Desk is used for chemical filter detection.

|

|

|

|

The Sewing Machine |

| The sewing machine is introduced from abroad and used for sewing filtering bag of bag-style filters. |

|

| |

|

GGVH High Velocity HEPA Filters

GGVH High Velocity HEPA Filters Mini-pleat Separatorless style HEPA/ULPA Filters

Mini-pleat Separatorless style HEPA/ULPA Filters VH High Velocity HEPA Filter(Closed-pleated HEPA filters for AHU)

VH High Velocity HEPA Filter(Closed-pleated HEPA filters for AHU) WCB Chemical Air Filter

WCB Chemical Air Filter Air Filters for indoor application

Air Filters for indoor application

efficiency

Air Filter-Permeation rate & Resistance, with

the aerosol of the sodium chloride water

solution. It intrigues Na with H2 flame at a

high temperature to let it give off a

characteristic ray of about 589nm, and transfers

it to the current value by the optoelectronic

converter so as to get the initial efficiency of

each filter. Our factory uses the Na flame test

desk to detect each high-efficiency filter with

clapboard before ex-work.

efficiency

Air Filter-Permeation rate & Resistance, with

the aerosol of the sodium chloride water

solution. It intrigues Na with H2 flame at a

high temperature to let it give off a

characteristic ray of about 589nm, and transfers

it to the current value by the optoelectronic

converter so as to get the initial efficiency of

each filter. Our factory uses the Na flame test

desk to detect each high-efficiency filter with

clapboard before ex-work.

laser

particle counter with large flux to scan and

test the whole wind-out surface, the counter

gives out the quantity and particle diameter of

each dust.

laser

particle counter with large flux to scan and

test the whole wind-out surface, the counter

gives out the quantity and particle diameter of

each dust.